Being a fellow of many interests, I've always wanted a view camera to be able to play with movements and giant negatives. It may seem anachronistic in this age of phones with 20 megapixel optics, but view cameras offer the ability to correct perspective in-camera as well as other focus tricks, and the giant negatives (4x5 inches in my case) when scanned still offer far greater resolution than any digital camera.

View cameras can be bought complete relatively cheaply now, but of course I'd rather build one and challenge myself with a precision project. This won't be my first homemade camera: I've made dozens of pinhole cameras in the past, and most recently made this

simple large format camera.

My basic plan started by finding a lens of appropriate specs (135mm f 5.6 in this case) and price (almost cheap as dirt) on ebay, downloading

Jon Grepstads plans here, and sketching my ideas on my phone's

CAD program. My first diversion from Grepstad's plans was to order a cheap double dovetailed camera Arca Swiss compatible rail and a pair of compatible clamps from Ebay. These things are ubiquitous out there nowadays, and very inexpensive, though they take weeks to ship. The rail is really designed for mounting cameras with giant lenses, or stereophotography rigs, but will serve me fine for this camera.

Secondly, I want to have a smaller front standard to make for a more compact total kit.

The rear standard will also be redesigned with a different focusing screen spring mechanism and non-rotating back.

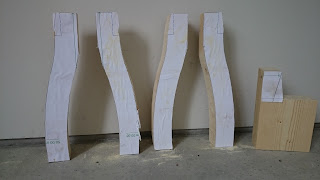

Most of the parts of the camera. I had a little black walnut, and procured a little more (including veneer) for this project.

The first diversion from the plans: I'm using polycarbonate for my focusing screen. It needs a light texture on it, so I taped a piece of 1000 grit wet/dry paper on a sheet of glass, and using window cleaner for lubricant scuffed away. It worked admirably, though ultimately I may get another piece bead blasted for better uniformity.

After marking the film frame with a silver paint pen, I cut pieces of 5mm walnut as a frame for the ground glass.

These were just glued with contact cement on both sides of the glass, providing I rigid sandwich construction.

The larger black walnut pieces were dimensioned, and then I got to play with my newish moving fillister plane to make rabbets.

The frame was constructed with stopped sliding dovetails. I'm not too happy about the gappy joinery.

Nor am I happy with this eviden twist.

Glued up it's flat, but the joints are pretty ugly. I'm out of practice. And I really could have used a 1/8" chisel for this job.

The finished parts so far: focusing screen and rear standard, with the lens and monrail waiting for the rest of the components.