A couple of years ago I had dinner with Mr. Chris Schwarz after a Dutch Tool Chest course I took in England. Talking about Sweden he brought up a project he'd done called "The Skansen Bench" which I'd never heard of. To be honest, the name "Skansen Bench" doesn't say much, as there are probably hundreds of different benches on display there. Only later did I realize that this project is one reproduced by woodworkers everywhere after plans printed in Popular Woodworking. While I appreciate the idea, the dimensions of home center lumber don't really do the proportions of the original justice.

The bench would be better called "Älvros Bench" as it can be found at the Älvros Farmstead at Skansen, which is almost always open to the public. Even then the name isn't terribly descriptive since there are probably a half dozen benches at this site. The one on display is a copy, as the original has been archived in the Nordiska collection warehouses. Plans for reproducing the original were published in a popular Swedish woodworking book in the 1970s.

The bench is somewhat iconic, and can be seen as an inspiration for this bench made of dimensional lumber and to be found scattered about Skansen.

We needed a hallway bench as a place to sit and put on and take off shoes, as one doesn't typically tramp around a Swedish home in shoes. I found some planed lumber measuring 70x195 mm in 3.3 meter lengths at a lumberyard out in the archipelago, and bought one for just under 200 kr. Although the width is far less than the original, I designed my own version around the dimensions, with simplified legs and a narrower top. Upon arriving home with my stock, I had to buck it up in the garage before bringing it inside.

As my jigsaw didn't have blades for the capacity of the wood, I grabbed my crosscut panel saw out of the workspace.

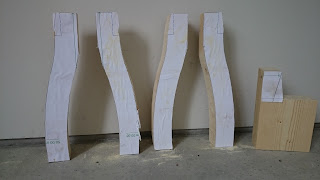

The legs I'd drawn up in my Android CAD program (which isn't working now that my phone updated to Marshmallow) and exported them as pdfs to print out at full scale. These I glued on with spray contact cement.

I took the sawbench and jigsaw with new, extra long blades out to the public access balcony to saw my stock into legs.

It was slow going in the 70mm thick stock, and the blade had a tendancy to drift to the left, so I planned my cutting around that and after about and hour I had my four legs roughed out.

No comments:

Post a Comment